Crystal Laser 2D & 3D Engraving

Precision and personalization are essential elements in many industries, including technology, jewelry, and the automobile sector, in today’s fast-paced world. As a cutting-edge technique, laser engraving provides unmatched versatility and precision for producing distinctive designs on a range of materials. We shall examine the advantages, uses, and most recent developments in the field of laser 2D and 3D engraving in this post.

What is Laser 2D & 3D Engraving?

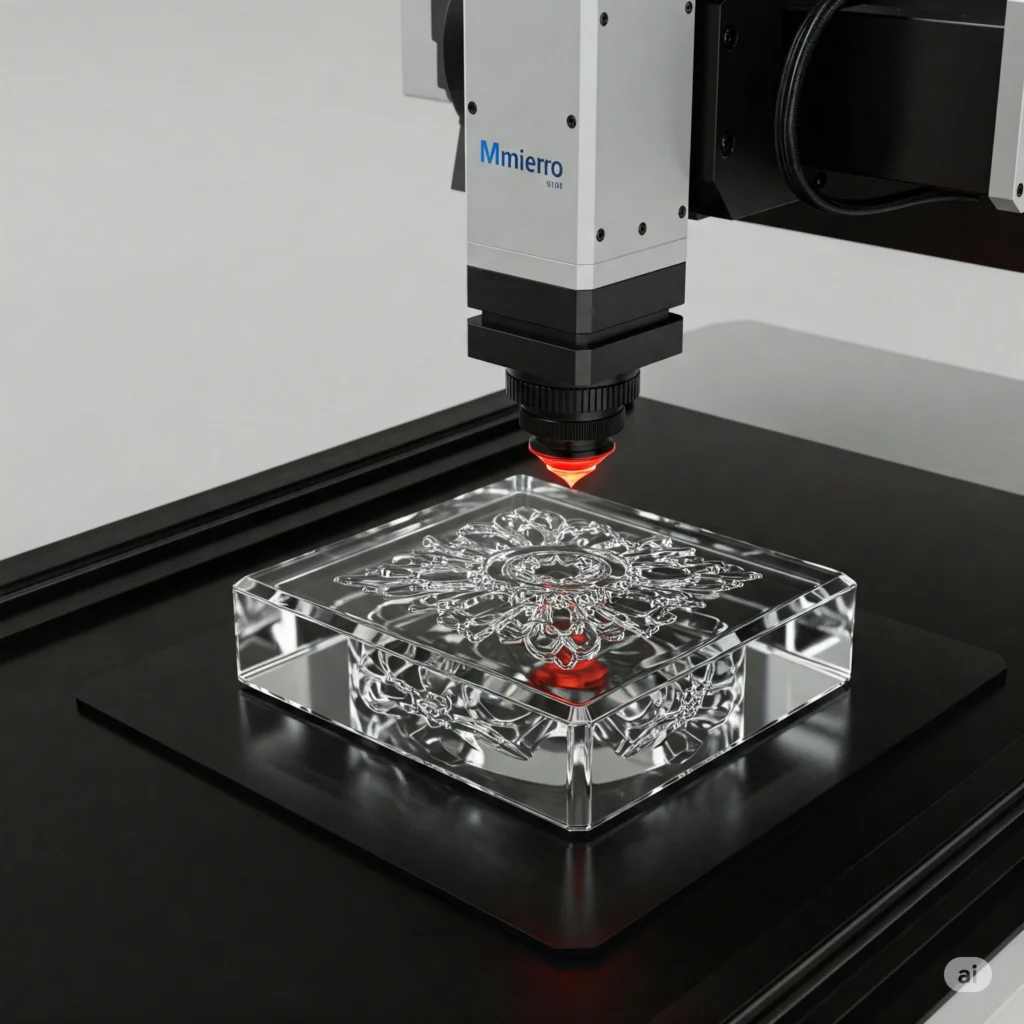

Laser engraving is a process that uses a high-powered laser beam to etch designs, text, or images onto the surface of a material. This technology has two main variations – 2D and 3D engraving.

2D engraving is the process of producing flat designs on a material, including elaborate patterns on jewelry, serial numbers on industrial parts, or logos on promotional items. A tiny layer of material is removed by the laser beam, leaving a precise, long-lasting impression.

By building layers of etched patterns, 3D engraving, on the other hand, gives the design depth and dimension. Personalized presents, architectural models, and artistic sculptures are frequently made using this technique. Complex details can be sculpted by the laser beam, making the finished object appear realistic and striking.

Benefits of Laser 2D & 3D Engraving

- Precision: The laser beam can produce complex designs with extreme precision, guaranteeing consistently excellent outcomes.

- Speed: Laser engraving is a speedy and effective procedure that works well for projects requiring a quick turnaround or bulk production.

- Durability: Long-lasting effects are guaranteed since laser technology produces engravings that are resistant to fading, abrasion, and corrosion.

Latest Advancements in Laser Engraving Technology

Integration with 3D Printing: To produce complex and multipurpose items, 3D printing technology is currently being used in conjunction with laser engraving.

AI Optimization: By using artificial intelligence to optimize engraving parameters, processing times are shortened and quality is raised.

Micro-Engraving: The ability to engrave on a microscopic level thanks to ultra-fine laser beams is creating new opportunities in sectors like electronics and healthcare.

When you choose our Laser 2D & 3D Engraving service, you can expect a seamless and efficient process from start to finish. Here is an overview of how we work:

- Consultation: Depending on the intricacy of the design and the material to be engraved, we will talk about your engraving requirements and provide you an estimate.

- Design: To get your permission, our team of graphic designers will collaborate with you to produce a digital mockup of the engraved design.

- Engraving: After the design is accepted, we will precisely and accurately engrave it onto the material using our state-of-the-art laser machines.

- Quality check: To make sure the engraving satisfies our exacting standards, we carry out a comprehensive quality check prior to finalizing the product.

- Delivery: Following the completion of the engraving, we will carefully package and transport the completed item to your home.